Environmental Test Chambers: Solutions for Global Compliance

Ormity designs and manufactures advanced Environmental Test Chambers engineered for precision, repeatability, and strict adherence to international regulatory frameworks. Our systems provide the controlled environments required by manufacturers, R&D centers, and certification bodies to validate products against water, high-pressure jets, and particulate ingress.

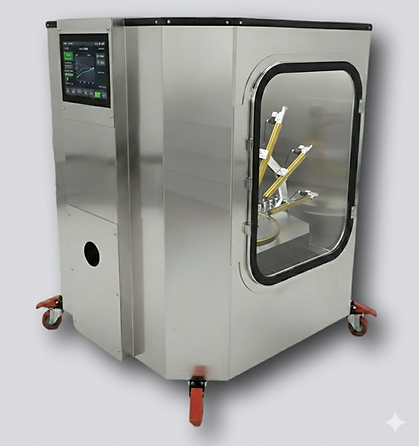

High-Pressure & High-Temperature Jet Testing – IPX9 / IPX9K

Extreme Thermal and Mechanical Stress Simulation.

Engineered for products facing intensive sanitation or extreme road conditions, Ormity IPX9K systems deliver high-energy water impact with unmatched thermal stability.

-

Primary Ingress Protection (IP) Standards:

-

IEC 60529: Standardized requirements for IPX9 high-pressure water jet testing.

-

ISO 20653 / DIN 40050-9: Specific IPX9K parameters for automotive engineering (80–100 bar at 80°C).

-

-

North American Industrial Standards:

-

UL 50 / UL 50E: Environmental standards for electrical enclosures (Type 4, 4X, 6P).

-

UL 508A / CSA C22.2 No. 14: Essential for wash-down rated industrial control panels.

-

-

Engineering Highlights:

-

Independent Jet Control: Four digital nozzles ($0^{\circ}, 30^{\circ}, 60^{\circ}, 90^{\circ}$) with real-time pressure and temperature monitoring.

-

Reinforced Structure: AISI 304 stainless steel chamber with high-pressure safety glass and triple-sealed doors.

-

Dust Ingress & Particulate Testing – IP5X / IP6X

The Mastery of Homogeneous Particulate Suspension. Ormity Dust Chambers solve the critical challenge of dust accumulation. Our technology ensures particulates stay in a constant swirling state, mimicking real-world desert or industrial ingress.

-

Primary Ingress Protection (IP) Standards:

-

IEC 60529: Validation for IP5X (Dust-Protected) and IP6X (Dust-Tight).

-

ISO 20653: Specific automotive dust protection classifications.

-

-

Extreme Environment & Defense Standards:

-

MIL-STD-810H (Method 510.7): Essential for sand and dust testing in military and harsh industrial applications.

-

RTCA DO-160: Environmental qualification for airborne equipment (Section 12).

-

-

Engineering Highlights:

-

Swirling Mist Technology: Engineered airflow prevents dust "dumping," maintaining a uniform, aerosolized fog throughout the test.

-

Integrated Vacuum Logic: Digital underpressure management for IP6X compliance, with flowmeters for precise differential control.

-

Water Ingress Protection (Spray Chambers) – IPX3 / IPX4

Repeatable Hydrological Impact Validation. Ormity Spray Chambers replace inconsistent manual methods with a fully automated, closed-loop system designed for precise water distribution and impact angles.

-

Primary Ingress Protection (IP) Standards:

-

IEC 60529: The global benchmark for certifying IPX3 (spraying) and IPX4 (splashing) protection.

-

ISO 20653: Specific requirements for automotive and road vehicle components.

-

-

Complementary Durability & Guidelines:

-

IEC 60068-2-18 (Test R): Utilized strictly as an environmental durability reference; distinct from primary IP certification requirements.

-

-

Engineering Highlights:

-

Servo-Driven Oscillation: Jitter-free motion with programmable angles up to ±180° for absolute cycle consistency.

-

Smart Water Management: Integrated filtration and recirculation system to prevent nozzle clogging and maintain constant flow rates.

-